The focus of this research is to analyze the benefits of using plain foam core over a scored core in vacuum infused composites. The comparison includes mechanical properties and weight variation. The research explores an alternative solution to scored foam cores in infusion processing that will yield a lighter and stronger fiber reinforced composite.

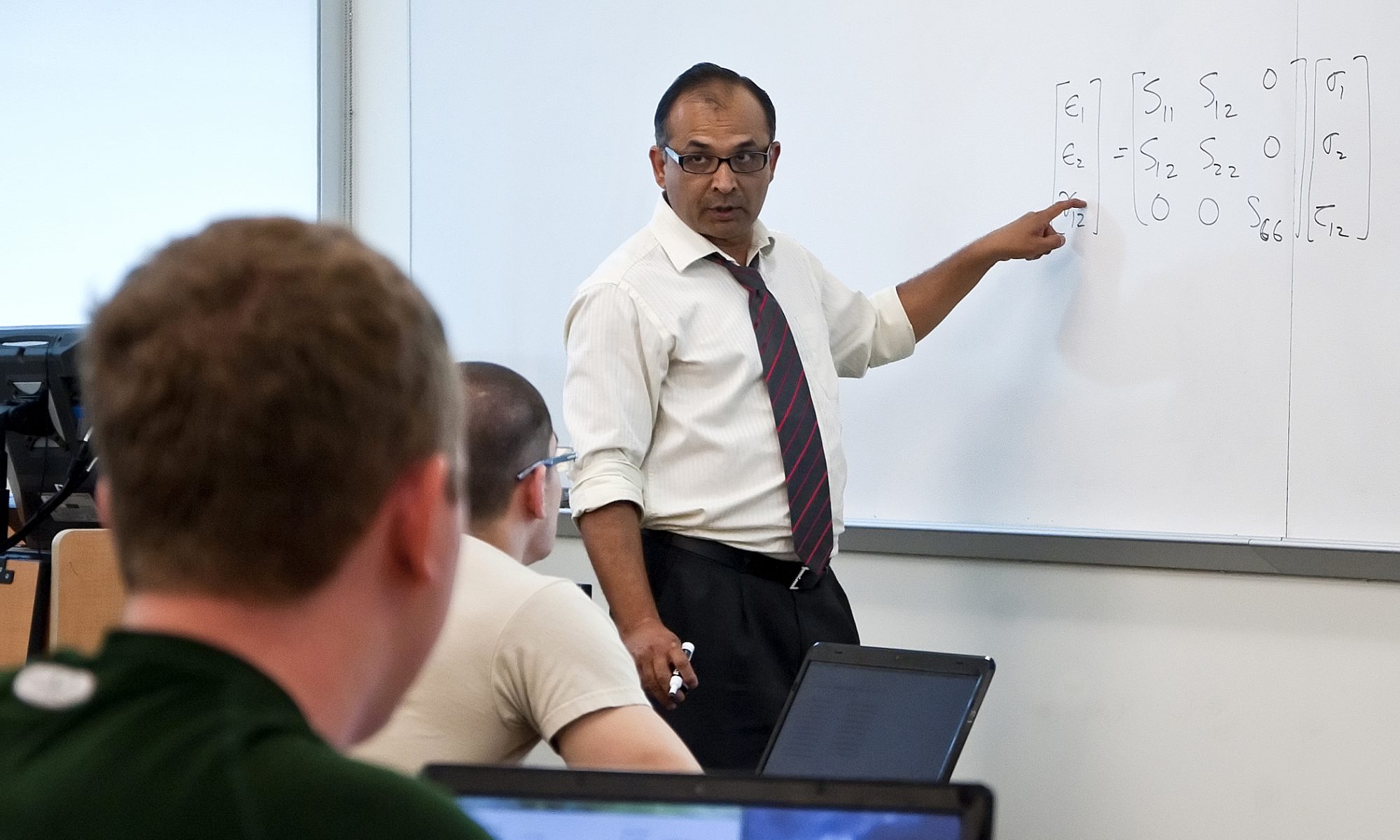

Experiments were prepared in accordance with ASTM standards to determine sandwich beam flexural strength. The specimens were composed of PVC (Poly Vinyl Chloride) foam sandwiched between E-glass/polyester face sheets. The samples were processed with the same catalyst ratio, ambient temperature, resin viscosity, fiber volume fraction and fiber orientation to ensure that core scoring is the only variable present.

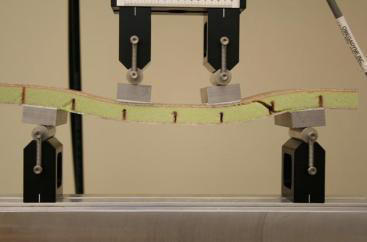

A four-point test was used to load the samples in a flexural condition and load span lengths were configured to ensure core shear failure. The samples with the plain core showed a 25 percent increase in flexural strength and an eight percent decrease in mass. The processing method provides mechanical and weight advantages while increasing processing cost due to additional resin port requirements.

A four-point test was used to load the samples in a flexural condition and load span lengths were configured to ensure core shear failure. The samples with the plain core showed a 25 percent increase in flexural strength and an eight percent decrease in mass. The processing method provides mechanical and weight advantages while increasing processing cost due to additional resin port requirements.